Sustainability

Sustainability

Over the years, sustainability at URC has become more than just compliance, but a responsibility to protect and create lasting value for our people, communities, and planet.

With our commitment centered on our stakeholders, we actively listen and engage with our employees, consumers, partners and suppliers to identify what key sustainability issues matter to them the most. These conversations have helped us refine and improve our strategies across our Focus Areas:

Natural Resources – embedding resource efficiency into our operations, optimizing energy and water use while minimizing waste.

Products – ensuring food safety, innovation, and alignment with URC’s strong wellness criteria.

People – fostering a safe, supportive, and growth-oriented environment for employees while effecting positive change in the communities where we operate.

Supply Chain – focusing on responsible sourcing, promoting transparency, and strengthening supplier relationships.

Economic Performance – embracing business practices that create shared success, ensuring long-term growth that benefits both URC’s stakeholders and the environment.

From baseline exercises and awareness campaigns in 2018 to the refinement of the “Live Sustainability, Live URC” framework in 2024, we have been hard at work developing a sustainability approach that is sharp and truly in sync with URC values.

Live Sustainability, Live URC Framework

Uplift People’s Lives

Robust Portfolio

Care for the Planet

Sustainability

Over the years, sustainability at URC has become more than just compliance, but a responsibility to protect and create lasting value for our people, communities, and planet.

With our commitment centered on our stakeholders, we actively listen and engage with our employees, consumers, partners and suppliers to identify what key sustainability issues matter to them the most. These conversations have helped us refine and improve our strategies across our Focus Areas:

Natural Resources – embedding resource efficiency into our operations, optimizing energy and water use while minimizing waste.

Products – ensuring food safety, innovation, and alignment with URC’s strong wellness criteria.

People – fostering a safe, supportive, and growth-oriented environment for employees while effecting positive change in the communities where we operate.

Supply Chain – focusing on responsible sourcing, promoting transparency, and strengthening supplier relationships.

Economic Performance – embracing business practices that create shared success, ensuring long-term growth that benefits both URC’s stakeholders and the environment.

From baseline exercises and awareness campaigns in 2018 to the refinement of the “Live Sustainability, Live URC” framework in 2024, we have been hard at work developing a sustainability approach that is sharp and truly in sync with URC values.

Live Sustainability, Live URC Framework

Uplift People’s Lives

Robust Portfolio

Care for the Planet

LIVE UP

Uplift People’s Lives

At URC, our journey has always been anchored on our people and the communities we serve.

We recognize that our workforce is not just a part of the organization, they are the driving force behind everything we do. With 13,952 individuals making up our diverse team, we continue to build a strong, purpose-driven company. Across locations and generations, we come together with a shared purpose to delight consumers, create value, and contribute meaningfully to society.

We believe that uplifting communities begins within by ensuring the well-being, growth, and empowerment of our own people. At the same time, we remain deeply committed to the communities around us through our Corporate Social Responsibility programs, which are thoughtfully designed to help address shared sustainability challenges and foster inclusive progress.

People

Employee data

13,952

Total No. of Employees as of 2024

Quantity

Units

By Gender

a. Number of female employees

4,397

#

b. Number of male employees

9,555

#

By Age Group

a. 26 and below

3,098

#

b. 27-41

7,291

#

c. 42-56

3,363

#

d. 57 and up

200

#

By Contract Type

a. Regular

12,405

#

b. Consultant, FTE & Project based

787

#

c. Probationary

760

#

By Length of Tenure

a. < 1 years

1,507

#

b. 1-3 years

3,153

#

c. 3-5 years

1,512

#

d. 5-7 years

1,545

#

e. 7+ years

6,235

#

Quantity

Units

By Rank

a. Executive/Senior Management

78

#

b. Rank & File

8,285

#

c. Supervisor

1,737

#

d. Manager

1,167

#

e. Seasonal

368

#

f. Professional / Technical

368

#

By Business Unit

a. BCF PH

4,061

#

b. BCF International

5,437

#

c. AIG

669

#

d. Flour

455

#

e. SURE

2,246

#

f. Main

486

#

g. Packaging

598

#

Attrition rate¹

9.2

%

Ratio of lowest paid employee

against minimum wage²

1:1

ratio

Occupational Health & Safety

Ensuring a safe and healthy workplace for our employees is central to how we operate at URC. We are deeply committed to providing a safe, healthy, and supportive environment where every employee feels protected and empowered.

Guided by our Safety Policy, we actively promote the identification and management of risks, integrate Occupational Health and Safety (OHS) into all aspects of facility operations. To strengthen this foundation, we established the Safety and Labor Relations Council which is a cross-functional body dedicated to addressing safety concerns, driving strategic interventions, and ensuring compliance across all sites.

We are deeply committed to providing a safe, healthy, and supportive environment where every employee feels protected and empowered.

73,815,426

Total Man-Hours in 2023

74,988,084

Total Man-Hours in 2024¹

Disclosure

2023

2024

Units

No. of work-related injuries²

286

231

#

No. of work-related fatalities

3

1

#

No. of work-related ill-health

-

-

#

No. of safety drills

130

159

#

LTIFR³

1.02

0.67

AIFR

3.87

3.08

Occupational Health & Safety

Ensuring a safe and healthy workplace for our employees is central to how we operate at URC. We are deeply committed to providing a safe, healthy, and supportive environment where every employee feels protected and empowered.

Guided by our Safety Policy, we actively promote the identification and management of risks, integrate Occupational Health and Safety (OHS) into all aspects of facility operations. To strengthen this foundation, we established the Safety and Labor Relations Council which is a cross-functional body dedicated to addressing safety concerns, driving strategic interventions, and ensuring compliance across all sites.

“

We are deeply committed to providing a safe, healthy, and supportive environment where every employee feels protected and empowered.

73,815,426

Total Man-Hours in 2023

74,988,084

Total Man-Hours in 2024¹

Disclosure

2023

2024

Units

No. of work-related injuries²

286

231

#

No. of work-related fatalities

3

1

#

No. of work-related ill-health

-

-

#

No. of safety drills

130

159

#

LTIFR³

1.02

0.67

AIFR

3.87

3.08

Reinforce Safety Program

Through our Reinforce Safety Program, we have instilled a culture of awareness, ownership, and accountability. Initiatives such as safety moments, mandatory localized trainings, and the Occupational Health & Safety Summit have built employee capability, while the introduction of structured supervisor routines and supplier checklists extended safety practices beyond our walls. To uphold discipline and reward excellence, we implemented clear safety violation protocols, expanded third-party compliance, and launched recognition programs that celebrate proactive safety leadership. These efforts, taken together, reinforce our deep commitment to a culture where safety is everyone’s responsibility.

Through this program, we have decreased our number of safety incidents from 286 to 231 and bolstered our culture of safety for all employees and partners.

Process Safety

Safety is the disciplined approach to managing hazards in industrial operations, preventing fires, explosions, and toxic releases through engineering, design, and management systems that protect people, property, and environment. At URC, we take process safety very seriously, as emphasized in our new company-wide Process Safety Management program.

To lay a strong foundation, we piloted a structured baseline study at BCFG Philippines. This assessment informed the implementation of immediate corrective actions and systemic improvements in safety protocols. As we scale this initiative across other business units, tailored assessments will help uncover unique safety challenges and build site-specific strategies. This year, we supported this rollout through 11 on-site coaching sessions, 4 awareness trainings, and knowledgesharing activities. Learnings from these engagements continue to enrich our risk management practices, empowering teams to act decisively and collectively safeguard our people, operations, and communities.

Health & Wellness Caravan

At URC, we recognize that employee wellness and mental health are essential to build a strong organization. URC is proud to prioritize employee well-being with its Health & Wellness Caravans, bringing free medical tests, treatments, and health education directly to our workforce. From eye exams to therapeutic massages, we have helped countless employees benefit from better physical, mental, and emotional health. We held a total of 17 caravans in 2024, reinforcing our belief that a healthy workforce is the foundation of a strong, thriving organization.

Safety Recognition Program

The LIFE Excellence in Safety Award celebrates the operations who exemplify outstanding safety performance and a strong culture of care, awarded to URC Thailand Plant 3 for its exemplary safety performance, alongside category wins for Leadership and People Engagement, Facilities and Infrastructure Safety Improvement, and Effective Safety Processes and Systems. Its Safety Officer, Siriporn Somchinda, was also named Best Safety Officer for her outstanding leadership. URC Pampanga 1 received the Best in Information, Education, and Communication Award, recognizing its commitment to empowering employees through safety awareness and training—reflecting URC’s continued dedication to a safe and resilient workplace.

Employee Training

Employee Training and Development

Disclosure

2023

2024

Units

Total training hours provided to

employees

351,724.76

422,362.54

hours

Average training hours provided

to employees

26.5

30.27

hours/

employee

Learning Interventions

One of the biggest investments we have given and continue to do so for our employees is the opportunity to learn and gain new skillsets. In 2024, we deepened this commitment by expanding training across leadership, technical, and agile programs. Through our Learning Management System (LMS), self-paced learning flourished, with over 7,000 hours consumed in just six months. We set a target of 24 training hours per employee, but our teams exceeded expectations, averaging 30.3 hours and contributing to over 422,000 total training hours, which is a 13% increase from the previous year. This momentum reflects not only our dedication to capability-building, but also our belief that when people grow, the whole organization thrives.

External Recognitions

In 2024, URC earned awards like Best Places to Work, HR Innovation, and Employer Branding—affirming its peoplefirst approach. Unlike traditional, siloed HR models, URC integrates technology, engagement, and culture. We also honored outstanding projects at the 2024 Annual URChoice Awards. Sixteen (16 awards) were presented across categories such as Business Excellence, Game Changer, Organizational Transformation, and People Focus, each serving as a reminder to continue pushing boundaries and pursuing excellence.

Communities

Corporate Social Responsibility

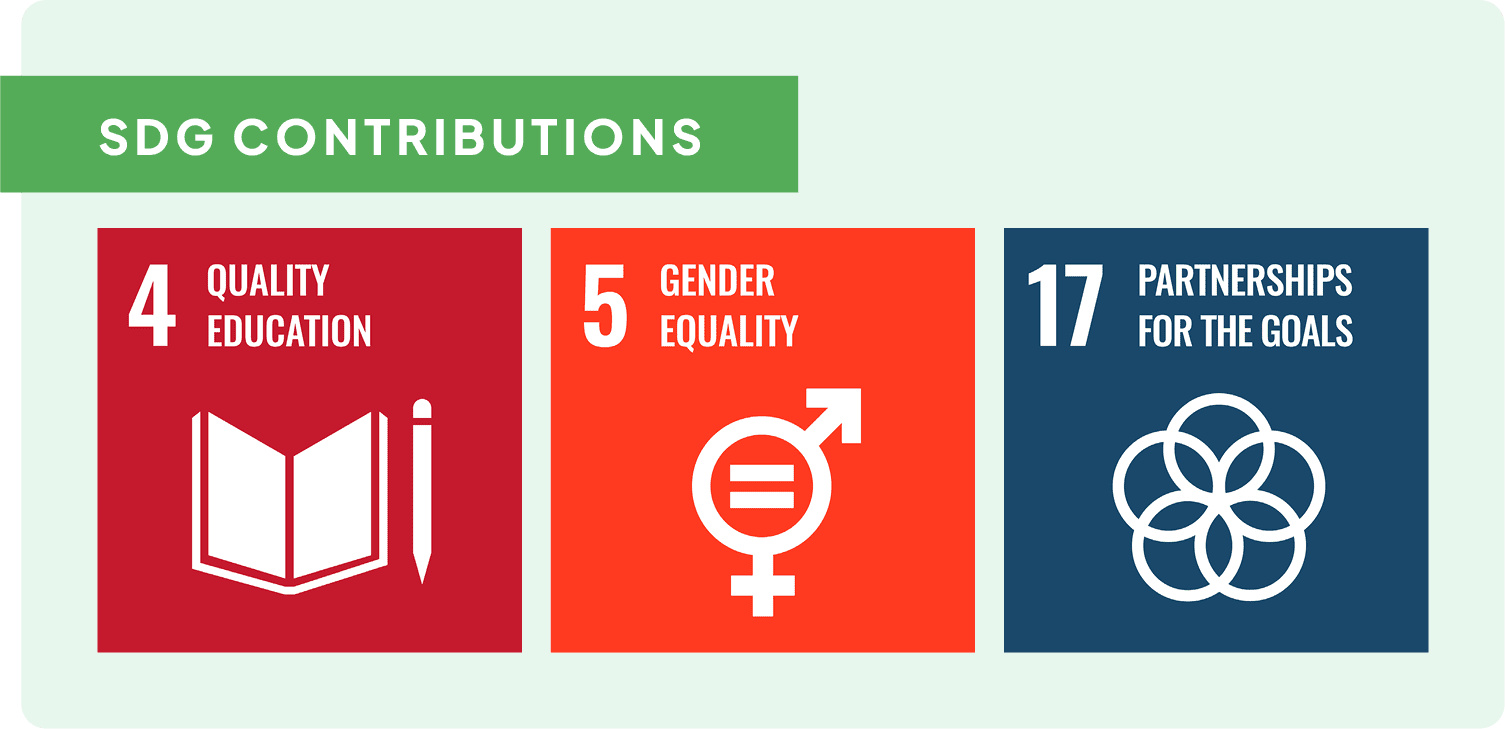

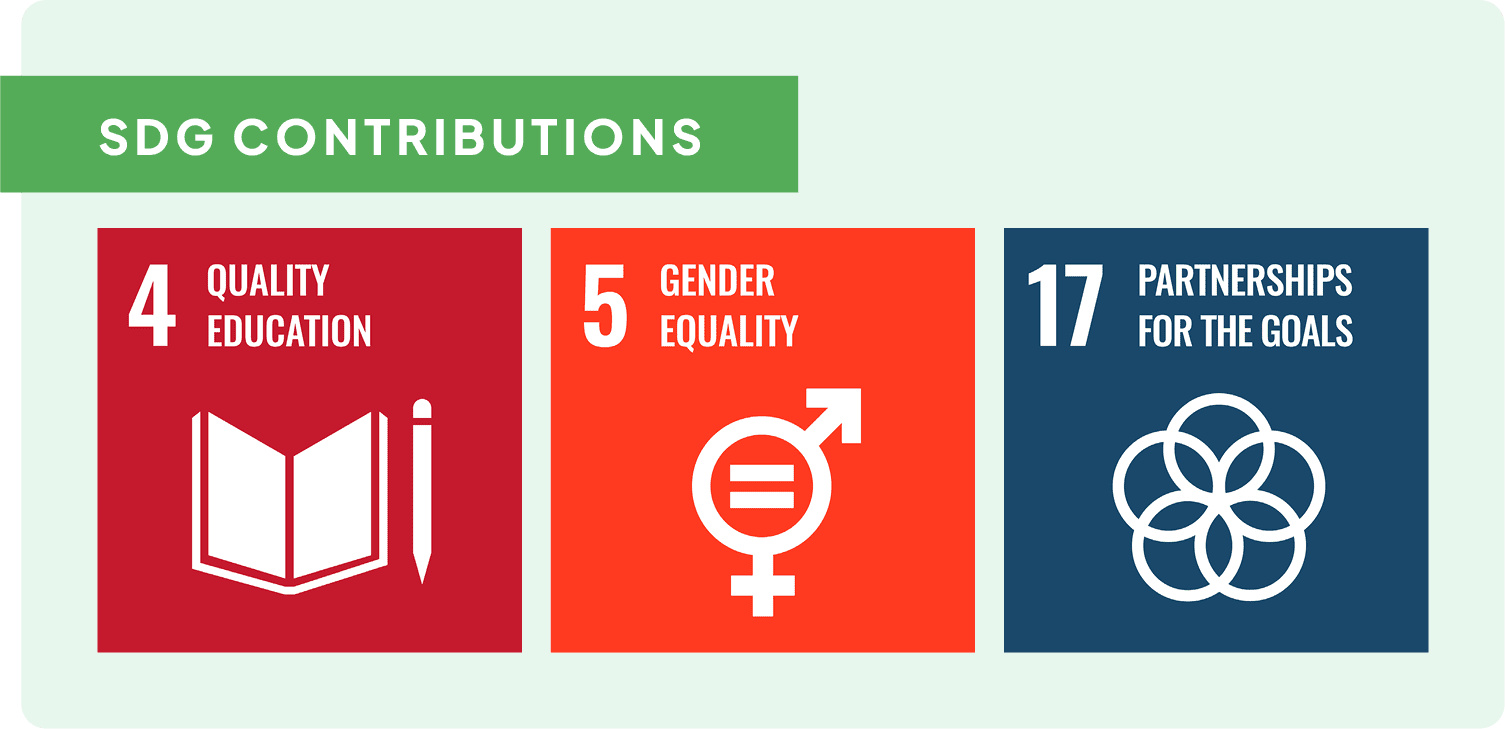

Juan Goal for Plastic

URC’s plastic waste collection program aims to engage and empower communities such as schools and barangays by incentivizing the proper segregation and collection of plastic waste. From its start in 2022, the program continues to drive environmental impact by engaging communities, fostering partnerships, and supporting compliance with Extended Producer Responsibility (EPR) laws. In 2024, the initiative collected 36 metric tonnes of plastic waste, with over 30 collection sites activated across various business units and partner communities.

Sustainable Potato Program

Potato is an important commodity for

URC and we recognize its importance

for food security. That is why, we extend our support to our local farmers in the Benguet, Cagayan de Oro, and Davao regions. This year, we signed a five-year Memorandum of Agreement with the Department of Agriculture to expand the Sustainable Potato Program, strengthening seed systems, training farmer organizations, and increasing productivity in key potato-growing regions. Since 2019, the program has distributed 506 metric tonnes of high-quality potato seeds across 202 hectares, generating P920 million in income for 14 farmer groups. The DA has committed additional funding for seed production, targeting 12,000 hectares of commercial potato farming.

Communities

Corporate Social Responsibility

Juan Goal for Plastic

URC’s plastic waste collection program aims to engage and empower communities such as schools and barangays by incentivizing the proper segregation and collection of plastic waste. From its start in 2022, the program continues to drive environmental impact by engaging communities, fostering partnerships, and supporting compliance with Extended Producer Responsibility (EPR) laws. In 2024, the initiative collected 36 metric tonnes of plastic waste, with over 30 collection sites activated across various business units and partner communities.

Sustainable Potato Program

Potato is an important commodity for

URC and we recognize its importance

for food security. That is why, we extend our support to our local farmers in the Benguet, Cagayan de Oro, and Davao regions. This year, we signed a five-year Memorandum of Agreement with the Department of Agriculture to expand the Sustainable Potato Program, strengthening seed systems, training farmer organizations, and increasing productivity in key potato-growing regions. Since 2019, the program has distributed 506 metric tonnes of high-quality potato seeds across 202 hectares, generating P920 million in income for 14 farmer groups. The DA has committed additional funding for seed production, targeting 12,000 hectares of commercial potato farming.

LIVE RIGHT

Robust Portfolio

LIVE RIGHT

At URC, we believe that living right begins with making the right choices, starting with the way we source, produce, and package our products.

Robust Portfolio

Our commitment to a robust and responsible portfolio is grounded in the belief that sustainability and quality must go hand in hand. Every ingredient we select, every innovation we introduce, and every package we design reflects our purpose of delighting everyone with good food choices.

Responsible Sourcing

URC is deeply committed to sustainable operations by ensuring that all raw materials are traceable, responsibly sourced, and compliant with the highest food safety standards. A core element of this commitment is the sourcing of key ingredients—such as palm olein and potatoes—from certified and credible suppliers.

In 2024, 60% of the palm olein we used was RSPO MB Certified, ensuring ethical practices. 100% of our chipping potatoes came from GAP certified suppliers, and the AIG business unit continues to use Sustainable US Soy.

Through our Responsible Sourcing Policy and Supplier Code of Conduct, we continue to influence our suppliers to uphold the highest environmental, ethical, and food safety standards.

LIVE RIGHT

Robust Portfolio

LIVE RIGHT

At URC, we believe that living right begins with making the right choices, starting with the way we source, produce, and package our products.

Our commitment to a robust and responsible portfolio is grounded in the belief that sustainability and quality must go hand in hand. Every ingredient we select, every innovation we introduce, and every package we design reflects our purpose of delighting everyone with good food choices.

Responsible Sourcing

URC is deeply committed to sustainable operations by ensuring that all raw materials are traceable, responsibly sourced, and compliant with the highest food safety standards. A core element of this commitment is the sourcing of key ingredients—such as palm olein and potatoes—from certified and credible suppliers.

In 2024, 60% of the palm olein we used was RSPO MB Certified, ensuring ethical practices. 100% of our chipping potatoes came from GAP certified suppliers, and the AIG business unit continues to use Sustainable US Soy.

Through our Responsible Sourcing Policy and Supplier Code of Conduct, we continue to influence our suppliers to uphold the highest environmental, ethical, and food safety standards.

Product

FSSC Certification

Food Safety and Quality Management

URC maintains incredibly high standards of quality and food safety across all our operations. We follow global standards and have even developed our own rigorous framework, including the One Good Manufacturing Practices (GMP) Requirements and URC Operational Requirements (URCORe) Integrated Quality and Food Safety Standards. These ensure consistency, compliance, and continuous improvement in manufacturing and sourcing. URC also conducts risk based internal audits to proactively identify and address potential issues, while investing in training programs to equip auditors with the skills needed to uphold food safety standards.

In line with our commitment to excellence, we are determined to achieve 100% sustained Quality and Food Safety Certifications for applicable manufacturing sites. This is done by adopting best practices in food safety management systems and pursuing globally recognized certifications schemes such as Food Safety System Certification (FSSC) 22000 with reputable certifying bodies. Maintaining the highest standards in quality and food safety is essential not only for compliance but also for building consumer trust and loyalty.

FSSC Certification

Quality Recognition Program

The PEARL Excellence in Quality Award is given to a Plant Facility that has embedded a Quality Culture which resulted in the achievement of exemplary performance for Quality and Food Safety. This award was presented to URC Vietnam Plant 2 for fostering a strong quality culture and achieving exceptional performance in quality and food safety. Its Quality Manager, Nguyen Thi Anh Ngoc, was also named Best Quality Assurance Head for her leadership in upholding food safety and compliance. Category awards included the Brand Quality Seal Award to URC San Pablo Plant for consistent product quality, the Globe Excellence Award to URC Vietnam Hanoi for global compliance and operational continuity, the Quality Lens Award to URC Vietnam Plant 2 for promoting continuous improvement, and the Flask Award to URC Thailand Plant 5 for integrity in quality testing and laboratory excellence.

Nutritional Quality

Wellness Criteria

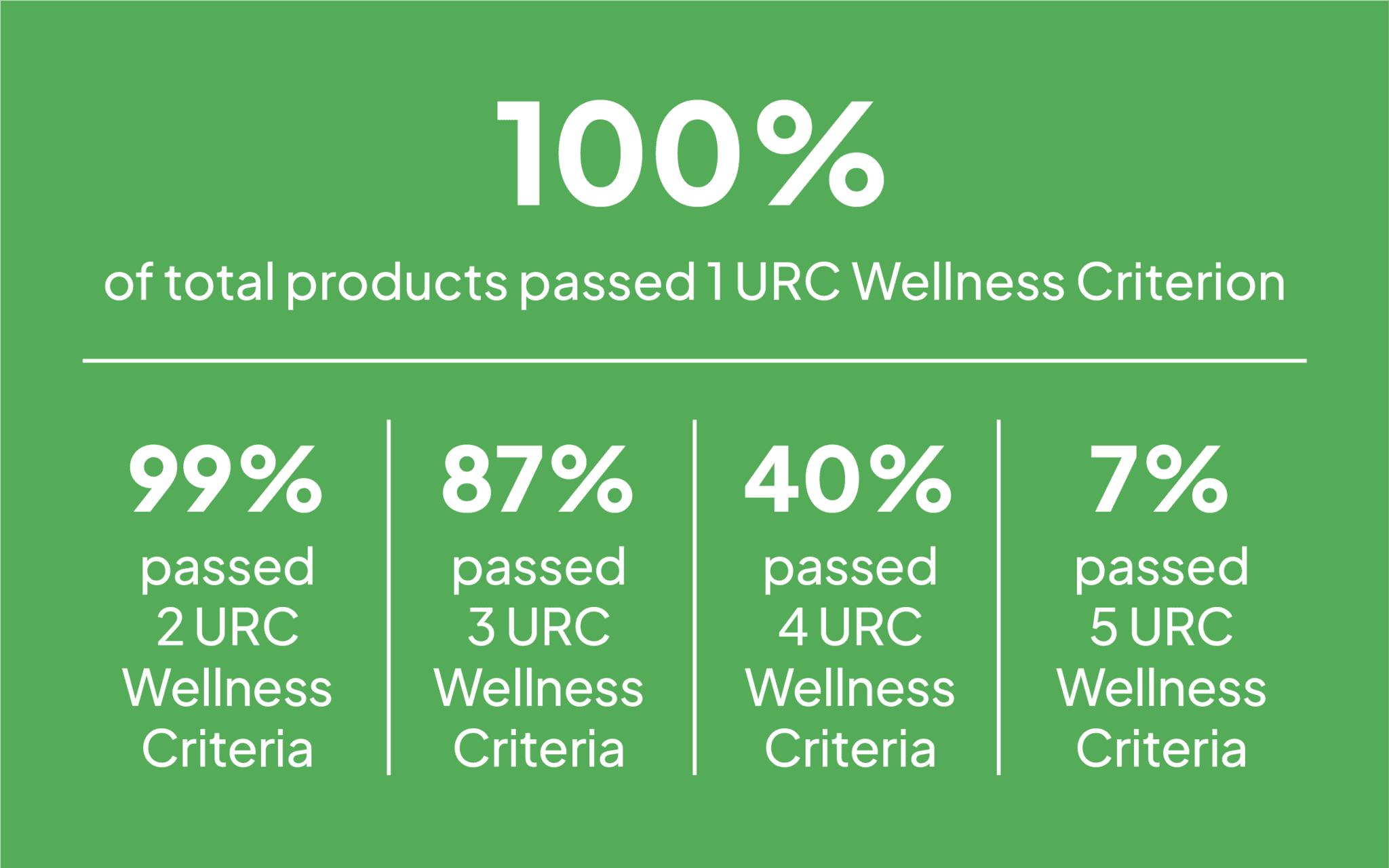

URC’s Wellness Criteria is an internal guide used to improve the nutritional value of our products. Through this initiative, we are able to proactively address the possibility of stricter government regulations on sugar, sodium, fat, and other health & wellness components.

URC recognizes that wellness trends are evolving faster than expected, driven by a growing middle class and shifting regulations. To stay ahead, the company revised its Wellness Criteria in 2021, aligning with WHO guidelines to enhance product nutrition. URC upgraded its target for wellness criteria to achieve 100% total products passing 3 wellness criteria by 2030.

In line with our commitment to excellence, we are determined to achieve 100% sustained Quality and Food Safety Certifications for applicable manufacturing sites.

In 2024, the total URC Wellness Score (using the updated criteria) indicated that:

The aim of URC is for 100% of our products to meet at least three wellness criteria by 2030. In addition, we have introduced innovations like VegiGood, a breading mix of tasty seasonings, spices, real carrots, and malunggay, as well as nutrient-rich products in Indonesia and Vietnam, which incorporate 100% natural ingredients and utilize functional quality ingredients.

Packaging

Plastic Footprint

Packaging Reduction

At URC, we are reducing our plastic footprint by:

- Reducing trim waste of total print width by incorporating tonal scales in wrapper design

- Reducing cut length of Great Taste Premium and Granule sticks

- Reducing the thickness of shrink wrap used for C2

- Light weighting of C2 bottles

We also reduced our plastic weight in the Refresh water bottles without compromising the quality of the product. The original 330 mL bottle weighing 13 grams was replaced with a 350 mL version weighing only 7.85g, while the 500 mL dropped from 16g to 8.85g. We are also redesigning our coffee mix wrappers to be recycle ready, supporting sustainability and resource efficiency.

LIVE CLEAN

Care For The Planet

At URC, we believe that caring for the planet is a reflection of our values and a commitment to the creating a sustainable future.

As environmental challenges grow more urgent each day, we choose to lead with purpose, responsibility, and action.

Our commitment goes beyond sustainability, it is a pledge to protect the natural systems that sustain all life, from the air we breathe and the water we drink, to the precious resources that support our communities and fuel our growth.

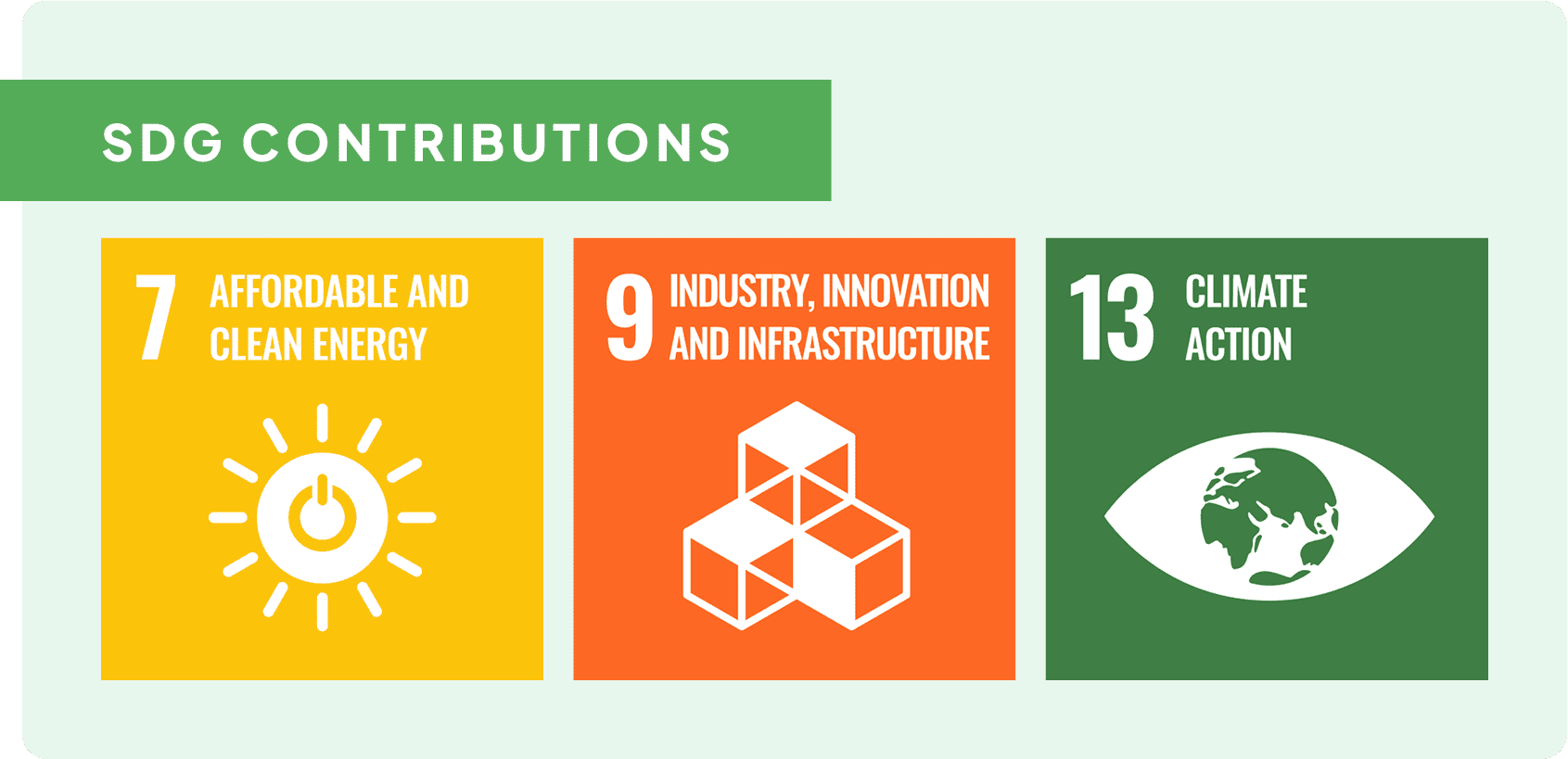

Climate Action

We live in a world where the effects of climate change are no longer a distant threat but already unfolding in real time. As a company grounded in purpose, we recognize our duty not only to reduce our environmental footprint but to become part of the global solution. Climate action is at the core of our sustainability commitment.

At URC, we understand that protecting the planet means securing the future of our people, our business, and our communities. As a testament to this, we anchor our climate action plans on its target to reduce its energy use ratio (EUR) by 30% compared to 2020 levels, and ultimately achieve Net Zero by 2050.

Energy Efficiency

URC is committed to effectively manage its energy usage by improving energy efficiency. Anchored on our target to reduce our EUR by 30%, we continuously look for opportunities to improve operations, eliminate wastages, and reduce overall energy demand.

Energy Consumption within the Organization

Disclosure

2023⁴

2024

Units

Energy consumption (Renewable sources)¹

1,750,194

24

1,569,015

22

GJ

%

Energy consumption (Electricity from non-renewable)

822,726

11

827,580

12

GJ

%

Energy consumption (Fossil fuel)²

4,764,013

65

4,595,754

66

GJ

%

Energy consumption (Total)

7,336,934

6,992,349

GJ

Energy Use Ratio (EUR)³

2.7

2.63

GJ/MT

Energy Intensity

46.93

43.49

GJ/MnPHP

Note: Data covers information of total URC (BCF-PH, Flour, SURE, AIG, head offices, and external

distribution centers in the Philippines, BCF-INT excl. China)

purchased electricity from renewable sources through Retail Electricity Contracts

owned vehicles

Energy Efficiency Improvement in Operations

Over the years, project teams were formed to conduct feasibility studies and continuously implement improvements focused on areas such as electricity conservation, reduction of fuel consumption (coal, diesel, LPG), solar, and biofuels as alternatives. In 2024, these projects evolved to focus on improving the operation of boilers through the Project BOPIES, which has delivered substantial results, cutting energy use by 15% for coal and 3% for diesel. This improvement in efficiency led to a massive PHP 73 million in cost savings.

Utilization of Biomass & Biogas as Fuel Displacers

In a bid to strengthen our reliance on alternative fuels, URC has turned to using biomass and biogas from manufacturing by-products to generate steam and electricity. Many of our sugar mills and distilleries are powered by bagasse (a by-product of sugarcane milling), spent wash, and biogas power. Animal waste, coffee grounds, and tea leaves fuel farms and food plants. In 2024, these efforts generated 659,694 GJ of energy, displacing 9.5% of total energy consumption.

Many of our sugar mills & distilleries are powered by bagasse (a by-product of sugarcane milling), spent wash, and biogas.

GHG Emissions

Greenhouse Gas Emissions

Disclosure

2023

2024

Units

Direct (Scope 1)

GHG Emissions

433,700

408,227

Tonnes CO₂e

Fugitive Emissions¹

31,166

25,902

Tonnes CO₂e

Energy Indirect (Scope 2)

GHG Emissions2

156,990

154,180

Tonnes CO₂e

Total (Scope 1 + Scope 2)

GHG Emissions

590,690

562,339

Tonnes CO₂e

GHG Intensity

3.77

3.50

Tonnes CO₂e/MnPHP

Note:

- GHG Emissions cover information of total URC (BCF-PH, Flour, SURE, AIG, head offices, & external distribution centers in the Philippines, BCF-INT excl. China). This includes fugitive emissions.

Emissions from biomass are considered biogenic emissions and should be tracked separately as per the GHG Protocol and are thus, not included in the overall GHG emissions inventory.

2023 numbers have been restated due to changes in structure (acquisitions & divestments) and methodology improvements (improved emission factors).

Climate Action Program

URC kicked off its Climate Action Program (CAP) in 2024 to tackle greenhouse gas emissions head-on. Our bottom-up approach (operations to-corporate) supports teams with trainings on GHG fundamentals and decarbonization strategies.

The program streamlined energy savings and renewable energy (RE) adoption projects by categorizing them into key decarbonization levers to measure their impact to URC’s GHG emissions for the next three years.

Since 2020, URC has seen a decrease in its Scope 1 & 2 emissions, with a big focus on increasing RE mix to sustain momentum on reducing emissions. As we gear towards 2050, the CAP will continue to provide URC with sound projections that serve as foundations to make data-driven decisions as we continuously evaluate our Net Zero target.

“

Since 2020, URC has seen a decrease in its Scope 1 & 2 emissions, with a big focus on increasing Renewable Energy mix.

Solar Power

URC has been integrating solar energy into its operations since 2019, installing solar panels across twelve facilities with a total capacity of 18.1 megawatts peak (MWp). A notable project this year is the 1 MW ground mounted solar farm at the La Carlota Distillery Plant in Negros Occidental.

In 2024, URC’s solar initiatives contributed 63,173 gigajoules (GJ) to the company’s energy consumption, avoiding approximately 6,217 tons of CO2 emissions compared to if it was purchased from the grid.

Biomass Power Generation

URC’s bagasse-fired power plant in Kabankalan, Negros Occidental generates electricity used for both operations and for distribution to the national grid. By maximizing this biomass energy, URC reduces its reliance on fossil fuels for sugar manufacturing, all while contributing to the Philippines’ renewable energy mix.

Purchased Electricity from Renewable Energy Sources

Boosting our transition to renewable energy sources, we have secured partnerships with Retail Electricity Suppliers to provide our facilities in the Philippines with electricity generated from solar and geothermal energy. In Vietnam, we have existing Power Purchase Agreements (PPA) that provide electricity generated from solar energy.

We will continue to maximize opportunities to utilize renewable energy in purchased electricity for all of our operations. As a sign of progress towards this goal, 51% of electricity the company purchased came from renewable energy sources.

Climate Action Program

URC kicked off its Climate Action Program (CAP) in 2024 to tackle greenhouse gas emissions head-on. Our bottom-up approach (operations to-corporate) supports teams with trainings on GHG fundamentals and decarbonization strategies.

The program streamlined energy savings and renewable energy (RE) adoption projects by categorizing them into key decarbonization levers to measure their impact to URC’s GHG emissions for the next three years.

Since 2020, URC has seen a decrease in its Scope 1 & 2 emissions, with a big focus on increasing RE mix to sustain momentum on reducing emissions. As we gear towards 2050, the CAP will continue to provide URC with sound projections that serve as foundations to make data-driven decisions as we continuously evaluate our Net Zero target.

“

Since 2020, URC has seen a decrease in its Scope 1 & 2 emissions, with a big focus on increasing Renewable Energy mix.

Biomass Power Generation

URC has been integrating solar energy into its operations since 2019, installing solar panels across twelve facilities with a total capacity of 18.1 megawatts peak (MWp). A notable project this year is the 1 MW ground mounted solar farm at the La Carlota Distillery Plant in Negros Occidental.

In 2024, URC’s solar initiatives contributed 63,173 gigajoules (GJ) to the company’s energy consumption, avoiding approximately 6,217 tons of CO2 emissions compared to if it was purchased from the grid.

Biomass Power Generation

URC’s bagasse-fired power plant in Kabankalan, Negros Occidental generates electricity used for both operations and for distribution to the national grid. By maximizing this biomass energy, URC reduces its reliance on fossil fuels for sugar manufacturing, all while contributing to the Philippines’ renewable energy mix.

Compliance Assessment

Boosting our transition to renewable energy sources, we have secured partnerships with Retail Electricity Suppliers to provide our facilities in the Philippines with electricity generated from solar and geothermal energy. In Vietnam, we have existing Power Purchase Agreements (PPA) that provide electricity generated from solar energy.

We will continue to maximize opportunities to utilize renewable energy in purchased electricity for all of our operations. As a sign of progress towards this goal, 51% of electricity the company purchased came from renewable energy sources.

URC continually aims to lessen the load on the planet through climate action initiatives.

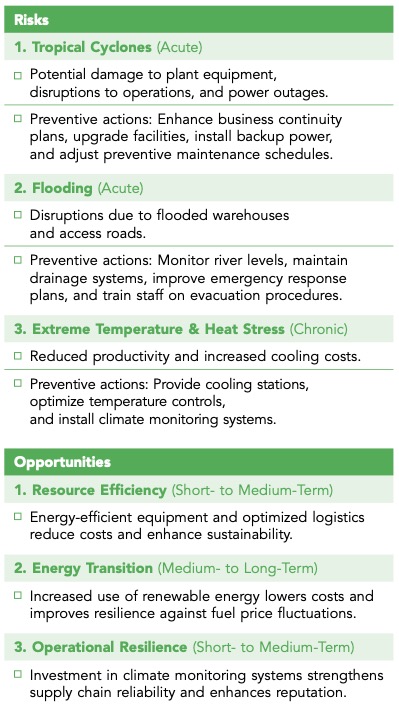

Climate Related Risks & Opportunities

URC continually aims to lessen the load on the planet through climate action initiatives, keeping the business resilient and ready for the impacts of climate change. That is why URC is keen on identifying climate-related risks and opportunities.

Driven by leadership support and the contributions of the Corporate Governance and Sustainability Committee, the company has identified the following physical risks and opportunities:

Water Management

Water Efficiency

Reduce, Reuse, Recycle

This three-R mantra is a powerful directive when it comes to reducing water consumption. To achieve this, URC has implemented rainwater harvesting, leak detection, and process improvements in its facilities. It reuses water by recovering steam, recycling rinse water, and repurposing it for cleaning and irrigation. The company also recycles treated wastewater for cooling systems and initial raw material washing.

In 2024, the company reduced its water use ratio (WUR) by approximately 38% against its 2020 baseline data.

Compliance Assessment

URC ensures compliance by regularly assessing facilities’ adherence to permits and environmental, health, and safety (EHS) standards. Monthly tracking and the Integrated EHS Assessment (IEHSA) help manage risks and guide improvements. The program has expanded internationally, ensuring all sites meet strict local regulations.

In 2024,

the company

reduced its water

use ratio (WUR) by

approximately 38%

against its 2020

baseline data.

In 2024, the company reduced its water use ratio (WUR) by approximately 38% against its 2020 baseline data.

Water Consumption within the Organization

Disclosure

2023

2024

Units

Water withdrawal¹

18,122,829

14,535,765

Cubic meters

Water consumption²

10,831,247

7,569,606

Cubic meters

Water withdrawal³

936,929

672,021

Cubic meters

Water intensity

69

47

Cubic meters

/ MnPHP

Water Use Ratio (WUR)⁴

6.82

5.58

Cubic meters / tonnes

Note: Data covers information of total URC (BCF-PH, Flour, SURE, AIG, and BCF-INT excl. China)

Waste Management

Solid Waste Reduction

As part of its commitment to reducing waste and achieving its zero-waste-to-landfill goal, URC continuous to implement several sustainability initiatives focused on effective waste management. This covers an end-to-end approach where URC manages both post-industrial and post-consumer waste challenges.

In 2024, we reduced our solid waste by 29.64%. We will continue working hard to reduce these numbers further. Our vision is to offer comprehensive, heartfelt ideas on how to manage all our waste, with some notable programs below:

Segregation at Source

Effective waste management starts at the source. URC facilities actively practice waste segregation to improve proper disposal and recycling efforts – not only as good practice, but also as an example for others.

Solid Waste

Disclosure

2023

2024

Units

Total solid waste generated

2,454,320

1,726,786

Tonnes

Recyclable (Biodegradables¹ and Non-Biodegradables²)

616,317

357,729

Tonnes

Incinerated

0

0

Tonnes

Residual/Landfilled³

24,057

20,885

Tonnes

Renewable⁴

1,813,946

1,348,172

Tonnes

Note: Data covers information of total URC (BCF-PH, Flour, SURE, AIG, and BCF-INT excl. China)

* 2023 numbers have been restated to excl. China

Hazardous Waste

Disclosure

2023

2024

Units

Total weight of hazardous waste generated¹

618

641

Tonnes

Total weight of hazardous waste transported²

375

372

Tonnes

Note:

Scrap Recovery

It is important to the company that we engage with third party service providers who shares our commitment to dispose wastes responsibly. URC produces a lot of high-value waste materials which is recovered and reintegrated into the recycling stream, in pursuit of a circular approach.

Use of Biomass and Discarded Animal Waste as Alternative Fuel

URC champions sustainable energy by utilizing biomass and various by-products as alternative fuel across its operations. As mentioned, our Sugar & Renewables (SURE) plants use bagasse and spent wash to produce steam, electricity, and biogas. The Agro-Industrial Group (AIG) converts animal waste into biogas to power its farms, while the Branded Consumer Foods Group (BCFG) repurposes coffee grounds, tea leaves, and sludge for energy in its facilities in San Pedro, Calamba, and Vietnam. These efforts significantly reinforce URC’s commitment to a circular, eco-friendly approach to energy.

Food Waste Management

URC recognizes that tackling food loss and waste is key not only to sustainability but also to addressing hunger and malnutrition. In 2024, URC continued its partnership with Scholars of Sustenance Philippines (SOS PH), supporting food rescue and redistribution to vulnerable communities. Through food collection and Rescue Kitchen programs, including a World Food Day volunteer event, URC helped reduce food waste while promoting sustainability and social responsibility.

Waste Management

Solid Waste Reduction

As part of its commitment to reducing waste and achieving its zero-waste-to-landfill goal, URC continuous to implement several sustainability initiatives focused on effective waste management. This covers an end-to-end approach where URC manages both post-industrial and post-consumer waste challenges.

In 2024, we reduced our solid waste by 29.64%. We will continue working hard to reduce these numbers further. Our vision is to offer comprehensive, heartfelt ideas on how to manage all our waste, with some notable programs below:

Segregation at Source

Effective waste management starts at the source. URC facilities actively practice waste segregation to improve proper disposal and recycling efforts – not only as good practice, but also as an example for others.

Solid Waste

Disclosure

2023

2024

Units

Total solid waste generated

2,454,320

1,726,786

Tonnes

Recyclable (Biodegradables1 and Non-Biodegradables2)

616,317

357,729

Tonnes

Incinerated

0

0

Tonnes

Residual/Landfilled3

24,057

20,885

Tonnes

Renewable4

1,813,946

1,348,172

Tonnes

Note: Data covers information of total URC (BCF-PH, Flour, SURE, AIG, and BCF-INT excl. China)

1. Biodegradable waste originated from plant or animal sources which may be broken down by other

living organisms

2. Non-biodegradable wastes were sold as scrap or returned to the recycling stream (e.g.: plastic

containers, rubber, and metal)

3. Residual/Landfilled –

non-potential and non-recoverable waste that are disposed to sanitary landfill.

4. Renewable are waste materials used as alternative fuel to generate the company’s own energy (e.g.: Coffee Spent Grounds used as alternative fuel to boiler to produce steam for the production)

* 2023 numbers have been restated to excl. China

Hazardous Waste

Disclosure

2023

2024

Units

Total weight of hazardous waste generated1

618

641

Tonnes

Total weight of hazardous waste transported2

375

372

Tonnes

Note:

1 Data covers information of total URC (BCF-PH, Flour, SURE, AIG, and BCF INT excl. China)

2 The difference in the quantity of hazardous waste generated and transported are stored onsite in DENR prescribed hazardous waste storage areas while waiting for schedule of transport and treatment.

3 2023 numbers have been restated to excl. China

Scrap Recovery

It is important to the company that we engage with third party service providers who shares our commitment to dispose wastes responsibly. URC produces a lot of high-value waste materials which is recovered and reintegrated into the recycling stream, in pursuit of a circular approach.

Use of Biomass and Discarded Animal Waste as Alternative Fuel

URC champions sustainable energy by utilizing biomass and various by-products as alternative fuel across its operations. As mentioned, our Sugar & Renewables (SURE) plants use bagasse and spent wash to produce steam, electricity, and biogas. The Agro-Industrial Group (AIG) converts animal waste into biogas to power its farms, while the Branded Consumer Foods Group (BCFG) repurposes coffee grounds, tea leaves, and sludge for energy in its facilities in San Pedro, Calamba, and Vietnam. These efforts significantly reinforce URC’s commitment to a circular, eco-friendly approach to energy.

Food Waste Management

URC recognizes that tackling food loss and waste is key not only to sustainability but also to addressing hunger and malnutrition. In 2024, URC continued its partnership with Scholars of Sustenance Philippines (SOS PH), supporting food rescue and redistribution to vulnerable communities. Through food collection and Rescue Kitchen programs, including a World Food Day volunteer event, URC helped reduce food waste while promoting sustainability and social responsibility.

Plastic Waste Diversion

Waste Management with Holcim

URC tackles plastic pollution through a circular approach, partnering with Holcim Philippines to manage industrial waste from its ESMO Plant, diverting it from landfills through pre- and co-processing. Expanding this effort, they teamed up with LGUs in Obando, Bulacan; El Salvador City; and Sto. Tomas, Pampanga to improve municipal waste segregation. This tripartite collaboration supports URC’s EPR compliance and sustainability goals, benefiting over 100 waste workers and reinforcing a circular, community-driven approach to plastic waste management.

Diversion Initiatives

As part of URC’s Extended Producer Responsibility (EPR) strategy, plastic waste collected from partner LGUs was processed by Holcim’s waste management arm, Geocycle. Through cement kiln co-processing, the waste was turned into alternative fuel, integrating it into Holcim’s industrial operations.

Environment Recognition Programs

The GREEN Excellence in Environment Award honors URC facilities that lead in responsible resource management. In 2024, URC Vietnam Plant 2 received the Green Excellence award, along with Best in Energy Efficiency Management, while its Pollution Control Officer, Gio Huynh Van, was recognized for outstanding environmental leadership. Other category winners include URC Thailand Plant 3 for Best in Waste Management, URC Pampanga 2 for Best in Water Management, and URC Canlubang Plant for Best in Nature Protection, each demonstrating URC’s collective commitment to sustainability and environmental stewardship.

Plastic Waste Diversion

Waste Management with Holcim

URC tackles plastic pollution through a circular approach, partnering with Holcim Philippines to manage industrial waste from its ESMO Plant, diverting it from landfills through pre- and co-processing. Expanding this effort, they teamed up with LGUs in Obando, Bulacan; El Salvador City; and Sto. Tomas, Pampanga to improve municipal waste segregation. This tripartite collaboration supports URC’s EPR compliance and sustainability goals, benefiting over 100 waste workers and reinforcing a circular, community-driven approach to plastic waste management.

Diversion Initiatives

As part of URC’s Extended Producer Responsibility (EPR) strategy, plastic waste collected from partner LGUs was processed by Holcim’s waste management arm, Geocycle. Through cement kiln co-processing, the waste was turned into alternative fuel, integrating it into Holcim’s industrial operations.

Environment Recognition Programs

A Worthy Journey

At URC, we believe that our sustainability agenda is both fulfilling and inspiring, a fitting legacy for a sustainable business enterprise.

By staying committed, being proactive and results-driven, we are building a future where business success and social responsibility go hand in hand towards lasting impact.

“

Love your work.

Work hard for it.

- John Gokongwei